5350 Pacific Way

Longview, WA 98632

Phone: (360) 423-2493

CDID #1 Long Reach Excavator

CDID #1 Long Reach Excavator

Levee Mowing Operations

Levee Mowing Operations

Levee Repar and Reconstruction

Levee Repar and Reconstruction

Unwanted Vegetation Removal

Levee Inspection Team

Levee Inspection Team

Video Inspection of Discharge Lines

Video Inspection of Discharge Lines

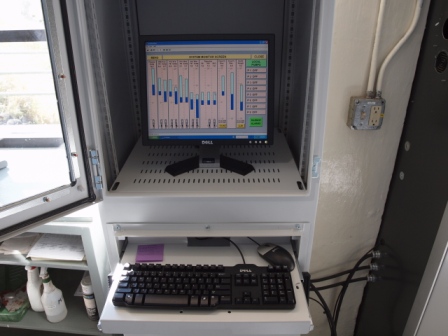

CDID #1 SCADA Pump Station Monitoring System

CDID #1 SCADA Pump Station Monitoring System

Reynolds Pump Station Outfall Repair

Reynolds Pump Station Outfall Repair

Removing Vegetation from Cutoff Slough

Removing Vegetation from Cutoff Slough

Operations and Maintenance

CDID #1 undertakes a comprehensive operations and maintenance program to ensure that all facilities are at a state of readiness to effectively handle internal stormwater and/or external flooding emergencies. Guidance for these endeavors is provided by both the District's Operation and Maintenance Plan and Emergency Action Plan.

CDID #1 has five full time maintenance emloyees; an operations foreman and four operators who are dedicated full time to District Operations and Maintenance (O&M). The District's maintenance shop and fleet of trucks and heavy equipment provide the tools necessary to keep District operations finely tuned.

In addition to internal O&M resources, CDID #1 maintains on-call contracts with a number of local engineering and surveying firms, electricians, and contractors in order to acquire additional O&M assistance as necessary.

CDID #1 Operations and Maintenance consists of the following components:

Levee System

Vegetation on the levees is controlled through system wide mowing typically at the beginning and middle of the growing season. Areas where soil becomes exposed due to traffic or repair work are promptly reseeded with erosion control grass species. Undesirable vegetation such as trees, shrubs, and invasive and noxious weed species are controlled through machine and hand removal, as well as treating with approved chemicals.

The tops of all levees are maintained with a drivable surface for access. Regular patrols identify issues that could affect access for maintenance or emergency purposes such as unwanted vegetation, illegal dumping, abandoned vehicles, and unauthorized structures.

District personnel also routinely inspect the levee for issues that may affect the structural integrity of the levee and hence its ability to perform adequately during storm events. These issues include, but are not limited to, vehicular damage, root intrusion, erosion, unauthorized construction activities, and animal burrows. Issues of significance are repaired in consultation with the Diking Engineer, and the USACE. Inspection intervals are increased during periods where high water is predicted and encountered, as well as after high water events to ensure no related damage is unaccounted for.

In addition to ongoing inspections conducted by District personnel, The District participates in two inspection programs undertaken by the US Army Corp of Engineers. These programs, identified below, ensure that the O&M work undertaken by the District is in conformance with Federal standards.

Rehabilitation and Inspection Program, ER 500-1-1 - Conducted

annually, this routine inspection takes approximately one day to

drive the levee system and assess whether the flood control works

will continue to provide the intended degree of flood protection and

determines if the maintenance program is adequate.

Periodic Inspection, National Levee Safety Program Act of 2007 - Conducted every five years, this is a more thorough review of all levee and stormwater removal systems. The inspection is conducted entirely on foot, takes approximately four days to complete, and consists of a large multi-disciplinary team of engineers.

Pump Stations

District pump stations are inspected and maintained at regular

intervals to ensure ready and reliable operation. The frequency of

the inspections and necessary maintenance is dependent on seasonal

operational requirements. The stations are visited several times a

week during normal work hours in the high stormwater flow season

from October through June. During large storm events, the stations

are monitored multiple times per day and around the clock if

necessary. Off-season, the stations may be visited as infrequently

as once a week.

Typical maintenance for each station consists of maintaining access,

cleaning up debris and garbage, removing accumulated vegetation from

intake screens, and regular building maintenance. Maintenance

specific to pumping equipment is typical for mechanical and

electrical equipment with all appropriate safety protocols followed.

Such maintenance typically includes; logging pump hours, replacing

fuses and relays, greasing and/or lubing bearings and mechanical

joints, filling oil reservoirs, and keeping equipment clean. Each

pump station maintains an inspection and maintenance checklist/log

that is filled out at each visit.

In order to provide additional safeguards against system failure and oversight of individual pump stations, the District maintains a radio operated Supervisory Control and Data Acquisition (SCADA) system. This system performs real-time tracking of water surface elevations, operational status, and alarm conditions for each facility and provides visual readout to District staff at the District Office, Maintenance Office, and Main Pump Station. This system enables District staff to respond quickly to issues that need attention and logs data that could be useful for trouble shooting system failures if they occur.

Sloughs, Ditches, and Drains

The sloughs, ditches and drains are maintained on a regular rotational basis. Maintenance work involves cleaning ditches of mud and debris, clearing and removal of vegetation and mowing on the banks and areas above water level, and repairing ditch banks that have eroded or slumped. The majority of ditches and drains are accessible by vehicle along at least one bank and maintenance is performed using excavation equipment (backhoe, track hoe, etc.) with the removed material being applied to the drainage way bank or placed in a dump truck and hauled to an approved disposal site. Some submerged vegetation is treated chemically. These treatments are contracted to a State certified contractor for performing this type of work and are performed in compliance with local, State, and Federal laws governing such operations.

Several ditches contain bypass structures with mechanical gates and/or trash racks and screens. All mechanical equipment is lubricated and operated at regular intervals to ensure reliability when needed. Grates and screens are inspected frequently and cleaned of all debris. Inspection intervals are increased during periods of rainy weather and significant storm events.